Tire Recycling Equipment Manufacture

Welcome to Engineering & Equipment Co. (EECO). EECO manufactures innovative tire recycling equipment that consistently delivers optimum safety, reliability, and output. Each of our expertly designed machines deconstructs a specific section of a tire to reduce overall volume, eliminate water retention, and add a range of processing options to create sellable goods from what would otherwise be a waste product.

A Cut Above

EECO machines are easy to own and operate. They come to you 99% ready to run and require very basic maintenance. Our Sidewall Remover, Bead Wire Remover, Tread Cutter, and truck tire variants use simple, standardized parts that are easily accessible either locally or directly from EECO. Our machines have the smallest footprint, lowest operational costs, and fastest ROI of any other tire recycling equipment suppliers, making us a clear leader among tire recycling machine manufacturers.

EECO has more than 30 years of experience in the tire recycling industry. When you purchase machines from EECO, you get the added benefit of working with a team of experts who are committed to providing personalized customer service and sharing their extensive knowledge of the industry.

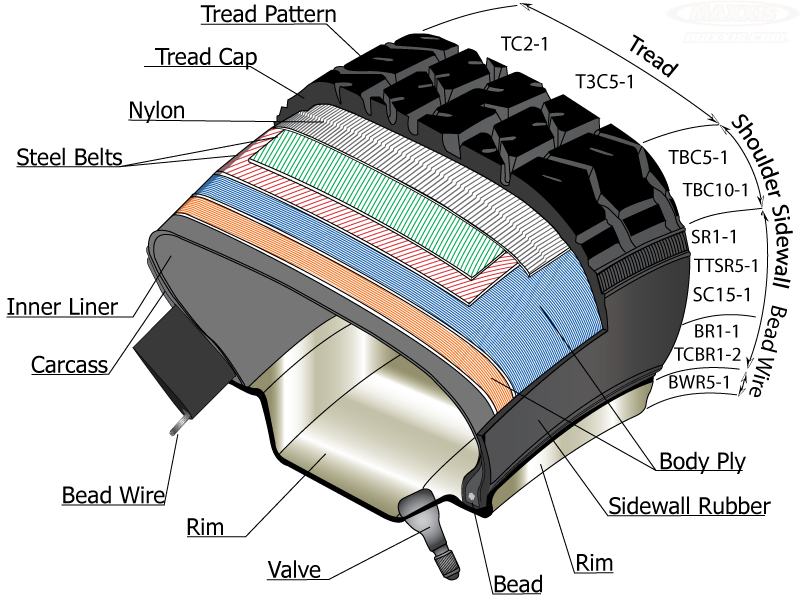

Anatomy of a Tire

Modern tires are a lot more complex than they would appear at first glance, just like the problem of what to do with them after they wear out. EECO's line of tire recycling equipment addresses both of these problems by cutting tires in just the right places, the way a surgeon might, to maximize the amount of tire material that can be recovered and recycled. Our machines are designed to work in stages; every stage removes a specific part of a tire, turning waste into valuable commodities.

Find out MoreEECO Tire Cutting Machines

Tire Recycling Machines

EECO’s state-of-the-art tire cutting machines work in three stages to break down tires into their usable parts, maximizing value and minimizing investment. Each of EECO's used tire recycling machines is designed to perform a role in deconstructing a specific part of a type or range of tires. This modular nature allows business owners to size their processing capacity to match their needs and grow over time without a large capital investment. Our standard line of scrap tire recycling machines deconstructs car and light truck tires from passenger vehicles while our truck tire variants deconstruct, you guessed it, truck tires as well as passenger car tires, aircraft tires, and super singles.

EECO has the finest industrial tire recycling equipment for sale in the USA and the most outstanding customer service you will find anywhere.

Know the Stages

Stage 1

Stage 1 machines are built to remove the sidewalls from whole tires. There are a number of reasons to remove sidewalls, including:

- Easier shredding. Sidewalls have a steel bead or belt that runs along the bottom edge. With the sidewalls removed, tire shredding can be done more easily.

- Tighter compressing. Isolated tread is easier to compress and bale, even for large truck tires.

- Less water retention. Once the sidewalls are removed, there’s nowhere for water to collect and sit. This means fewer mosquitos.

- More value. Once separate, treads and sidewalls can be sold as is or further broken down into smaller components. Tires contain rich resources that are useful in a variety of industries.

Stage 2

Stage 2 machines further process separated sidewalls and treads. EECO sells three basic types of stage 2 machines. Our bead removers isolate the steel bead from sidewall, leaving you with a rubber sidewall that is 100% steel-free and a band of steel that can easily be recycled. For further tread processing, we offer tread cutters and tread choppers. Waster tire cutters cut across the tread, helping break down the tire into more manageable chunks. Tread choppers and mobile tire shredders create chips for use as tire-derived aggregate or tire-derived fuel.

Stage 3

Stage 3 machines take tire materials from stage 2 and break them down even further. Stage 3 machines cut tread chunks into bands with straight edges and fixed widths and the tire sidewall chipper machine turns sidewalls into rubber mulch.

EECO’s waste tire recycling machines for sale come with our outstanding warranty and exceptional customer service. Call to ask about heavy tire recycling equipment prices today.